Enlarge

/

Heavy metal.

Lee Hutchinson

reader comments

182

with 111 posters participating, including story author

Share this story

Share on Facebook

Share on Twitter

Share on Reddit

Elite: Dangerous

and

Star Citizen

have a lot to answer for. Besides the money I’ve paid for the games themselves, I’ve sunk what can only be considered a truly embarrassing amount of cash into peripherals—things like the $450

Thrustmaster HOTAS Warthog

and the

$350 Oculus Rift DK2

. Still, something was missing from my space flight setup.

While both eyes and both hands had something to do, my feet remained unoccupied. I had two whole unused appendages that could be employed to make my spaceships do more things at once. Clearly this had to change, and there was only one solution—rudder pedals were my next step.

Further Reading

I’m not crazy (but I did buy a $450 HOTAS Warthog joystick)

But which pedals? There’s a smorgasbord of joystick choices that run the price gamut from cheap to ludicrous, but rudder pedals didn’t appear to cover the same range. The "high end" options all look like

variations

on

the same

sad

plastic theme

. I didn’t want to pair my high-end joystick with a bendy, flexy plastic contraption with open bearings that would gradually get crusty with dust and gunk, ultimately falling apart under my feet in the midst of a hectic space furball. I wanted something

awesome

.

And that’s how I found myself reading over my credit union’s procedure for international wire transfers, getting ready to send $500 to a Polish commercial bank account. The $500 would be withdrawn by a Belarusian gentleman who refers to himself as "Slaw," and Slaw would then hand-build me a set of rudder pedals out of powder-coated steel and springs and high-quality electronics. He has no website and takes orders via e-mail or through his

page. He doesn’t accept credit card orders or PayPal.

It felt a little weird. I wondered if I was putting myself on some kind of suspicious activity Homeland Security money laundering watch-list. But the draw of getting a perfect peripheral device overcame all caution, and I sent the cash. Then I waited.

How the hell did I get here?

When you fall into the high-quality rudder pedal rabbit hole, you quickly come to the realization that there are currently three front-runners for potential purchasing options. The first, and probably the most well-known, is the

MFG Crosswinds

pedals from MFG Šimundža. The next is the Slaw Device BF-109 pedals I went with. Both of these options will cost between $300-500, depending on shipping costs to your location. The third option is to actually source some genuine aircraft parts and can take the cost from "really expensive" into "home equity loan" territory. I’m crazy, but I’m not that crazy.

Advertisement

Neither the MFG Crosswinds nor the Slaw Device BF-109 pedals are mass-produced products; both are made to order and hand-assembled by craftsmen. The MFG Crosswinds are built from a wood composite material (Milan Šimundža, the designer, runs a furniture design business and has access to the machinery necessary to produce high quality composite wood), while the Slaw BF-109s are all metal. Between the Crosswinds and the BF-109s, I chose the metal Slaw Device pedals for the simple reason that they are available right now; Milan Šimundža is currently on pedal-hiatus. While you can sign up on a

waitlist

, he’s not making any more Crosswinds at the moment.

The Slaw Device pedals, on the other hand, can be purchased immediately. But again, there is no website to order from—to purchase, you contact the manufacturer directly through his

Facebook page

, or you dig up his e-mail address. I don’t do Facebook, so I e-mailed and waited.

The pedal man

The man behind the Slaw Device pedals is a fellow named Wiaczesław ("Вячеслав") Oziabło, a 36-year old Belarusian engineer living in the Polish town of Śmiłowo. The "Slaw Device" name he uses for his one-man company comes from his name (Slaw is a reduction of Slawa = Wiaczesław, "not of coleslaw!" he joked in e-mail). He’s a virtual pilot who built his first set of rudder pedals for himself due to the lack of acceptable non-plastic computer rudder pedals in the world.

"When the pedals are shown on the forums, I began to receive requests to make the pedal for others. So it all started," he explained in an e-mail with assistance from Google Translate. The resulting product weighs slightly more than 7 kg (about 15 lbs), and it feels sturdy enough to survive atmospheric re-entry from space.

Enlarge

/

Design plan for the Slaw Device pedals, showing dimensions.

Slaw Device

Oziabło works on the BF-109 order backlog in his free time, so his rate of production varies depending on the number of orders that are pending and the amount time he is able to spend in his workshop. Working evenings, his rate of production currently varies between zero and six BF-109 pedals in a given month. However, Oziabło says he has plans to begin working on pedal production full-time this year.

The Slaw Device

It took Oziabło five days to build my BF-109s (serial number 0063) and then another 15 days for shipping from Śmiłowo to Houston. When the box arrived, it was festooned with Poczta Polska stickers. Inside the sturdy cardboard was a set of styrofoam barriers, and the actual pedals were secured to a styrofoam bottom and wrapped in bubble wrap and a black plastic bag. I was at first a little worried about damage since the package contained a lot of open space and a few styrofoam bricks, but I needn’t have worried—the pedals were quite safe. Honestly, considering their weight, I’d be a lot more worried about whatever runs into them.

Advertisement

My pedals came in a box festooned with Poczta Polska stickers.

The packing job at first seemed a little haphazard, with loose styrofoam bricks rattling around in the empty spaces.

But the pedals themselves were solidly secured and wrapped.

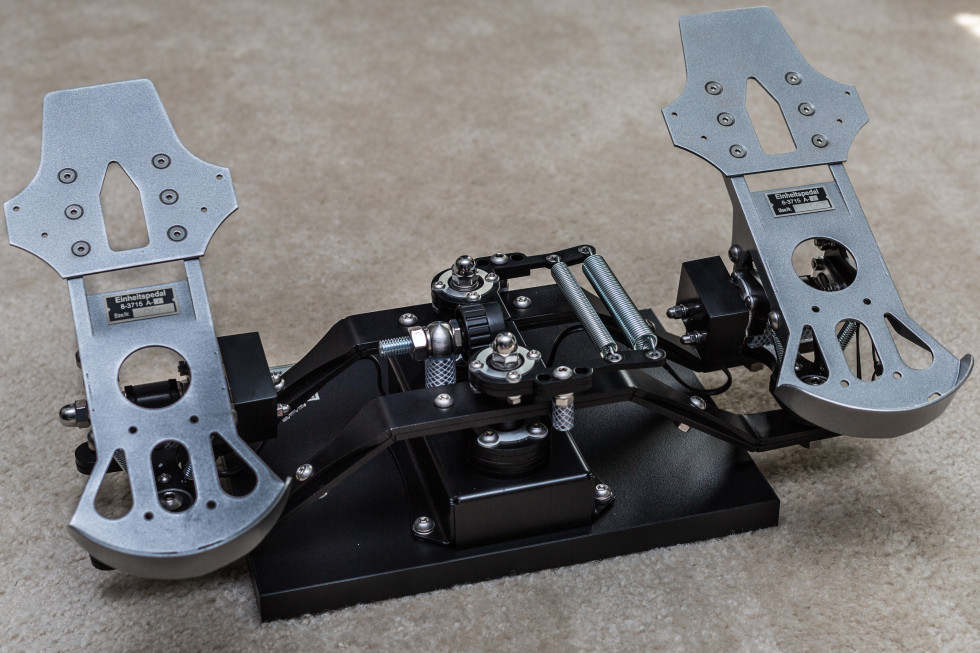

The BF-109s came immobilized by about a half-dozen zip ties, which I snipped away. My first impression on pulling them out of the packaging was one of

heft

—if I haven’t said it enough already, this is a solid piece of kit. Oziabło says most of the pedals' structure is steel (powder coated black), along with a few bits and bobs of aluminum. The moving components are affixed to a heavy base plate, which has four large strips of rubber on its bottom surface to keep it from sliding on your floor, no matter what your floor is made of.

The design of the pedals mirrors that of the World War II-era

Messerschmitt Bf 109

—hence the "BF-109" model number. The actual foot pedal components of the controller are mounted on a pair of arms, which are mounted on independent pivots so that they remain in parallel as the rudder pedals move forward and back. The arm and pivot arrangement means that the action of the pedals is linked—as one moves forward, the other moves backward. Additionally, the foot pedals themselves tip forward, going from their resting position at maybe 30 degrees up from horizontal to completely flat.

Top-down view of the entire pedal assembly.

Angled view on the double-pivot mechanism that rotates as the pedals are moved forward and back. Both springs came installed from Oziabło's workshop, but in practice you'd only use one (unless you want extremely stiff pedals).

Looking at the pedals from the front. USB connector is visible at the bottom.

The right-hand pedal in its standard position.

Right-hand pedal depressed. Tension is adjustable by moving the pedal's two springs to different attachment points.

Underside of the steel pedal.

There are plenty of adjustments that can be made. The left and right pedals can be attached to three different sets of mounting holes, allowing them to be moved several inches inward or outward (or canted toe-out or toe-in, to better line up with your resting foot preferences). The tension of the pedals’ forward and backward movement can be adjusted by attaching either of the two provided springs to two sets of mounting points, allowing six different levels of tension (eight if you use both springs simultaneously). I asked Oziabło what the tension measurements were for each of the springs and he admitted that he hasn’t actually measured them—he just went with springs that felt “right” to him. Having played with the available tension levels, his engineering judgment definitely jibes with my feet. All the available tensions feel proper, though I’ve found myself settling on the lighter spring on the closer holes for a very light amount of pedal effort.

The pedal actuation itself is also adjustable by moving each pedal’s two springs to different attachment points. Again, I didn’t measure the actual engagement force, but in its default position it feels good, so I’ve left it alone.