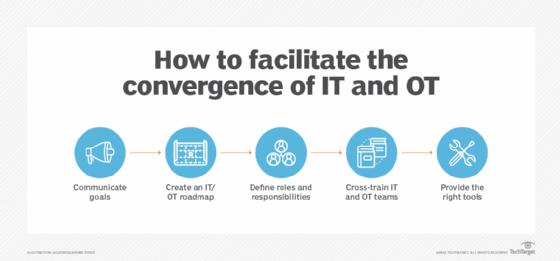

As Industry 4.0 and IIoT (Industrial Internet ofThings) concepts become real applications,an exciting conversation has developed centeredon the integration of information technology(IT) with operations technology (OT). Large IT companieshave actively promoted ideas like workloadconsolidation for businesses to optimize processes andbe more competitive. Some of the largest players inautomation technology (AT) are jumping on board.Greater system openness, real-time deterministiccontrol with many-core processors, the incorporationof web technologies and machine learning, amongother advances, are all possible through applyingpopular technologies to industrial applications.

IT and OT convergence offers incredible benefitsto machine control architectures today—just as it hasfor more than 30 years. While many suppliers arejust beginning to integrate PC-based technology intoindustrial automation, it is nothing new. The history ofIT-OT convergence in automation technology datesback to the early 1980s with the advent of the modernPC and those who saw its potential for industrialuse. The adaptation of these ideas follows the diffusionof innovations theory, which describes how newtechnologies are adopted in order by the innovators(2.5%), early adopters (13.5%), early majority (34%),late majority (34%) and, finally, the laggards (16%).

PC-focused innovationin the 1980s

During this era, the larger technology world beganto develop the personal computer (PC) and relatedtechnologies for widespread business and consumeruse far beyond 1970s levels. This led to transformationsin standard chip sets, board designs, and sophisticatedoperating systems. At that time, most industrialtechnology companies stayed away from the PCpath. The PLC platforms of the time used proprietarychip sets, board designs and, in most cases, programmingsoftware. Traditional PLC technology formachine control evolved much slower than it shouldhave due to an industry-wide aversion to change. Asa result, the paths of hardware PLCs and consumerPCs would not begin to converge for decades.

While the majority of industrial vendors andmanufacturers initially shunned IT technology on theplant floor, smaller start-up companies recognizedthat both technologies could coexist. Using provenindustrial standards and computer science innovations,smaller AT companies began the convergenceof IT and OT in manufacturing.

Early adoptersof the 1990s

In the 1990s, both technologies continued toadvance, with IT pioneers running laps around traditionalOT. The popularity of Windows exploded, andit became ubiquitous in nearly every area of technology.By launching Visual Studio in 1997, Microsoftcombined a number of programming languages ina single environment, which continues to evolve tothis day. Industrial vendors that began implementingPC-based automation technologies in the previousdecade saw significant gains in hardware and softwareperformance that far outpaced traditional PLCs. Thesuccessful companies created new tools for deterministic,real-time control that could run on industrialPCs with standardized operating systems.

More automation vendors saw this opportunityand launched computer-based controls. However,these early adopters realized that developing theirown software from scratch was quite costly. Theystarted using off-the-shelf real-time operatingsystems, but often didn’t widely promote thesolutions. Some notable crash-and-burns gavePC-based platforms a bad reputation during thistime. However, many platforms were providingincredible results in the field, extending their leadin performance over traditional PLCs.

Early majority from2000 onward

The turn of the millennium brought further developmentsin software and multi-core processors. MajorIT players like Intel, IBM, and Microsoft activelyexpanded into OT. Likewise, a determined subsetof the automation space kept integrating IT withincreased real-time capabilities.

Along with these automation and controladvances, another major development involved networking.Industrial Ethernet protocols, such as Ether-CAT, created significant performance improvementsand a path forward from legacy fieldbuses. This isanother example of IT and OT convergence, withEthernet merging with fieldbus technology. Ether-CAT eliminated the complexity and cost of switchesand additional hardware while providing deterministiccontrol with up to 65,535 devices per network. Thisresulted from the same PC-based control innovatorswho carefully considered the potential of industrialEthernet—combining its openness and acceptancewith the functionality of a fieldbus.

Today’s late majority

From automation software apps on smartphonesto many-core Intel Xeon processors in controllers,IT-OT convergence continues to acceleratetoday. For example, contemporary HMIs nowcommonly rely on web technologies, and standardssuch as MQTT and JSON are being implementedin IIoT contexts.

Gigabit Ethernet technologies such as Ether-CAT G are also becoming key as machines becomemore complex. The industry is also beginning toapply machine learning and other artificial intelligencetechnologies.

Fortunately, the reluctance of manufacturersto implement PC-based technologies continues toevaporate as they see the benefits of IT technologiesin industry. The decades of IT-OT advances haveshown that any IT principle carried over to OT productsmust be deterministic, reliable, available for manyyears and implemented efficiently. Done correctly,IT-OT integration produces results far better thanwhat traditional platforms can accomplish.

For more information:www.beckhoff.com/IoT